Revolutionary 3D-printed microwave splitters could reshape 5G and IoT tech

A team of researchers has developed a groundbreaking method for designing microwave power splitters. The approach combines inverse design algorithms with 3D printing to create highly efficient, customisable components. This innovation could transform how devices for 5G, IoT, and satellite communications are manufactured.

The project, led by researchers Zolfaghary Pour, Zhang, Liu, and their team, introduces an inverse design framework. Unlike traditional methods, this technique automates the discovery of complex structures that meet multiple performance targets at once. It also accounts for material properties and manufacturing limits, ensuring the designs are practical to produce.

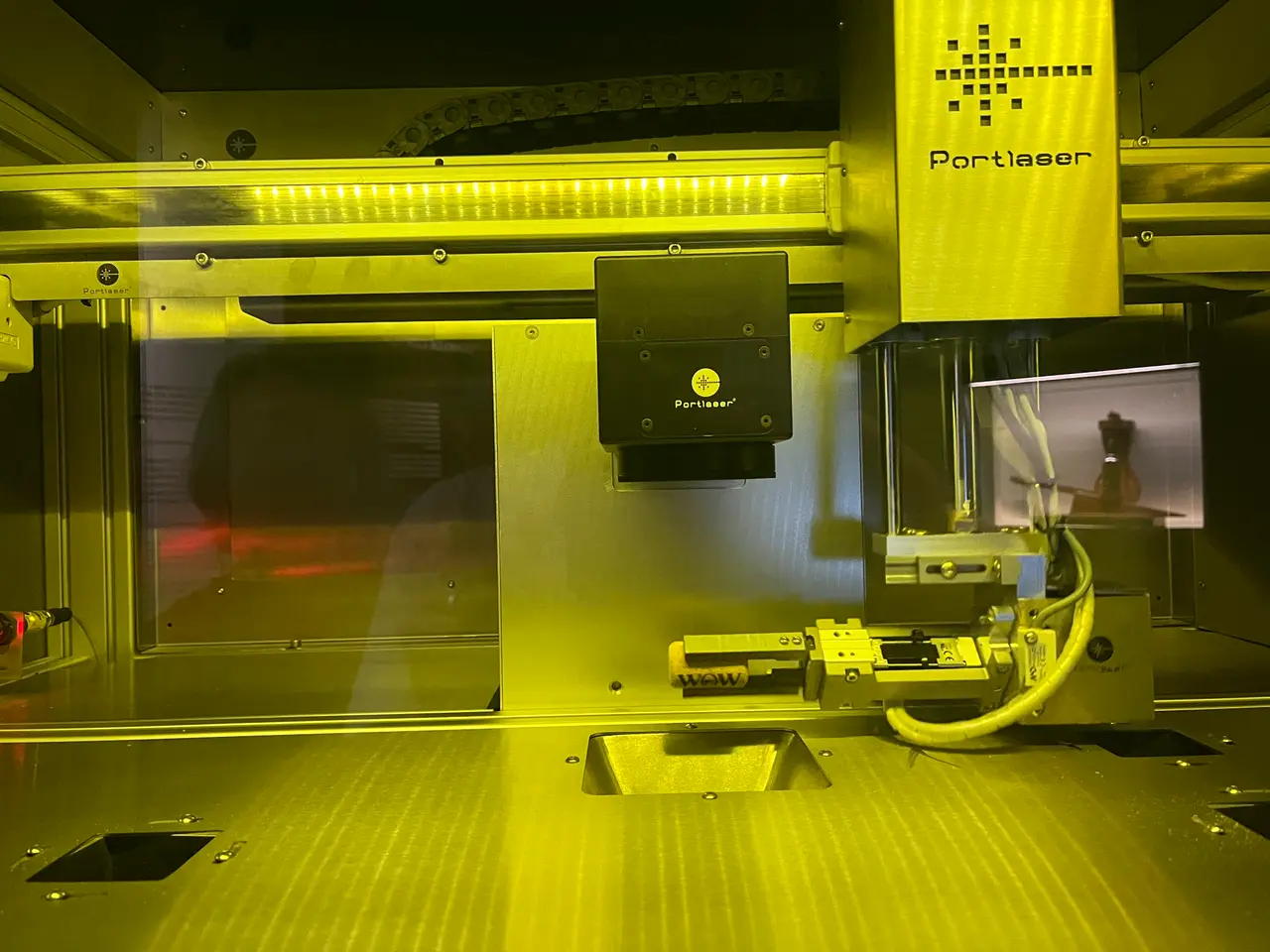

3D printing plays a key role in the process. It allows the team to fabricate intricate three-dimensional shapes with high precision, overcoming common production challenges. The flexibility of this method means it can adapt to new materials, including metamaterials or composites with specialised electromagnetic properties.

Testing confirmed the accuracy of the approach. Measured results closely matched simulations, proving the reliability of the design and fabrication pipeline. The resulting multiport power splitter supports multiple output channels while maintaining low insertion loss and strong isolation between ports.

The scalable nature of the framework offers clear manufacturing benefits. It enables rapid prototyping and customised devices without the need for costly retooling. This adaptability makes it ideal for emerging technologies like 5G networks, IoT devices, and satellite systems.

This research opens new possibilities for microwave and millimetre-wave components. The combination of inverse design and 3D printing delivers high-performance, customisable hardware. Such advancements could help meet the growing demands of next-generation communication systems.